Overview

Hydrocarbon solvent vacuum degreaser is the cleaning machine, which uses hydrocarbon solvent as the solution ,at the vacuum condition, process with cleaning flow of “pre-washing, vapor shower, endless shower, and vacuum drying ”,It has wonderful washing effort , saving energy ,and friendly to environment . This equipment is in high safety level ,high production efficiency and high reliability ,Very suitable for the mass-production cleaning process.

Main Application

Cleaning products before and after heat treatment.

◆ Superior Quality

The unique combination of vapor shower and cyclical shower ensures excellent cleaning effect; Vacuum drying under thermal state ensures complete dryness and no water residues.

◆Zero discharge

Complete sealed cleaning process ,recycle of cleaning solvent after reflux.Hydrocarbon solvent recycling,no other environmental emissions.

◆High Safety

All cleaning steps and regeneration procedures are performed under vacuum state which separate solvent from air. All pumps and sensors are proved to be intrinsic safety.

◆Low energy comsumption

All cleaning steps are operated in vacuum air-tight containers which is environment-friendly and energy-saving.

◆Easy Operation

Single chamber design, unique distilling system, compact structure and fully automatic operation system make it easy to operate and request low maintenance cost.

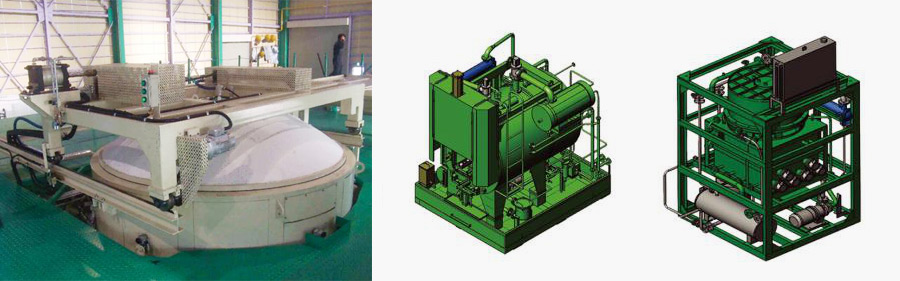

Horizontal type vacuum cleaning machine and Pit type vacuum cleaning machine are available upon the request. The unique combination of cyclic shower and vapor shower achieve excellent cleaning effect. Cleaning the parts with complicated shape and densely loaded by showering the solvent in vacuum state; Cleaning the parts with blind holes by vaporizing steam method in vacuum state; Cyclic shower with large flow solvent further clean the blind holds missed by vaporizing steam cleaning. Vacuum drying ensures complete dryness for cleaned parts.

The VCH series vacuum cleaning machine is equipped with a powerful regeneration unit to recycle the dirt solvent, which maintain the solvent purity above 99%. The solvent can be repeatedly used for a long time. Chlorine ion generated from heating additives in machining liquid may poses a danger to corroding the treated parts and equipments; Our unique FNAM neutralizing additives can eliminate its effect.

Type |

60/60/90 |

60/60/120 |

76/80/120 |

90/90/120 |

Treating Capacity(kg) |

400 |

600 |

1000 |

1500 |

Effective Size(mm) |

W600*H600*L900 |

W600*H600*L1200 |

W760*H80*L1200 |

W900*H900*L1200 |

Solvent Used |

Hydrocarbon Solvent |

|||

Solvent Volume(l) |

390 |

500 |

600 |

600 |

Power(kw/max) |

76 |

76 |

76 |

76 |

Cooling Water Volume(l/min) |

120 |

120 |

120 |

120 |