Process consulting

A powerful process support system and decades of experience help customers develop process blueprints, solve problems in process execution, and ensure that the quality of heat treatment is continuously controlled.

In the past 30 years, Fengdong has delivered customers thousands of sets of heat treatment equipment covering controlled atmosphere furnaces, vacuum furnaces, induction furnaces, non-atmosphere heating furnaces, and plasma furnaces etc. , accumulating a large number of process practices.

12 professional heat treatment machining centers, dozens of professional heat treatment process engineers have served in long-term in the production line, providing heat treatment processing service for thousands of customers every year, and accumulating a lot of process practical experience.

Powerful Internet-based heat treatment process database system to support you anytime, anywhere.

Solved the problem of accumulating knowledge. The process will not be lost, not have to be redevelpped or tested and not affect the heat treatment quality due to the enployees’ leaving his work.

It solves the big problem of knowledge sharing and does not need to do repeat work at a low level for a long time. The level of process can be further improved on the basis of predecessors.

Solved the problem of shortage of heat-treatment engineers, eliminating the need for heat-treatment engineers in every heat-treating and processing company, solving difficult-to-find problems for heat-treating engineers, and reducing company costs.

Solved the big problem of process development: high cost, long cycle, product process and quality instability.

Solved the needs of the chain management: to ensure the consistency of the processing technology and quality of different companies

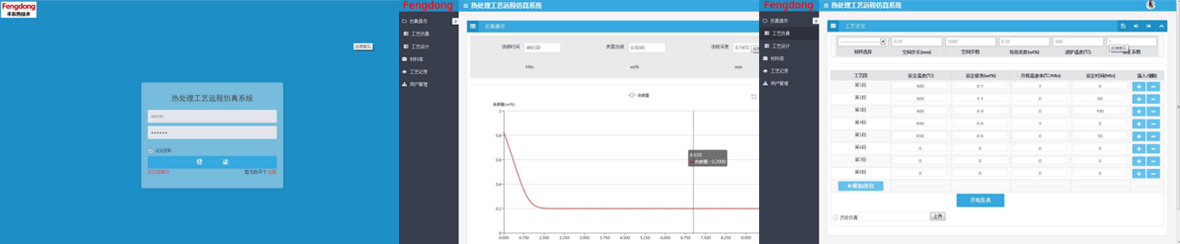

The Internet-based heat treatment process simulation system solves the annoyance of heat-treatment primary engineers, shortens the process R&D cycle, and reduces R&D risks and costs.

The 50 years of experience of the Shanghai Jiaotong University Pan Jiansheng academician team, the achievements of 25 year sincere cooperation between Fengdong and Jiaotong University. Remote bidirectional simulation can be realized. Process parameters can be input for mainstream process simulation, and the final product requirements can be input. The system automatically generates the recommended process.

Process consulting annual fee package (free consultation during the warranty period)

All packages are charged, and company sales staff can decide what level of free service they can provide during business negotiations as a preferential condition for customers.

Membership fee: 3,000 yuan / year, corporate customers can be eligible for membership. Members can exchang at any time in the member interactive area, and access to some free information.

Package 1: 9000 yuan / year, can provide process design proposal, online communication at any time, and access to the relevant design reference documents.

Package 2: 27,000 yuan/year, can provide 5 product process development plans (including verification data), online communication at any time, and access to the relevant design reference documents.

Package 3: 50,000 yuan/year, can provide 10 product process development plans (including verification data), online communication at any time, and access to the relevant design reference documents. Can provide technical training and skills assessment for 5 persons.

Package 4: 80,000 yuan/year, can provide 8 product process development plans (including verification data), online communication at any time, and access to the relevant design reference documents. Can provide technical training and skills assessment for 8 persons. And provide online process simulation design software and process database viewing interface.

Package 5: customized service. (process development, process technology training, online simulation design, third-party detection of parts physical and chemical features, heat treatment equipment performance and energy consumption detection, environmental factor detection, etc.)