Overview

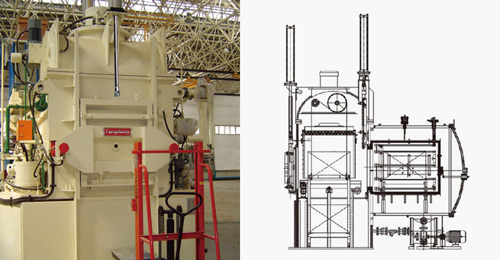

The vacuum double-chamber oil quenching furnace has the function of vacuum heating and oil quenching, with the option of 2 bar air cooling, providing more process selection methods and processing applications range. Widely applicable to vacuum heat treatment of precision parts of high, medium and low alloy steels.

Main Application

Quenching/Annealing/Brazing, solution, ageing etc.

◆ Hot zone is made of hard graphite felt plates with long life time.

◆ High temperature uniformity and heating efficiency.

◆Vacuum-tight and insulation double sealing structure of middle door ensures good sealing effects, optimum treatment results and low operating costs.

◆ Optimum utilization of the cooling chamber due to adopt the special inner driving structure.

◆ Cooling chamber door for is vacuum/overpressure tight with clamping mechanism, cooling pressures up to 2bar abs.

◆ The front door adopts a vertical upward opening method and can be combined with other heat treatment equipment to form an automatic production line.

◆ Exact temperature and process control.

◆ Free programmable control of all process.

◆ Equipment visualization with touch panel.

◆ Total automation functions.

◆ Parts Charging management and documentation function are available.

Type |

40/40/60 |

60/60/90 |

80/80/120 |

90/90/120 |

|

Effective Dimensions(mm) |

400*400*600mm |

600*600*900mm |

800*800*1200mm |

900*900*1200mm |

|

Rated Temperature |

1300℃ |

||||

Temperature Uniformity |

<±5℃ |

||||

Electrical connections |

Rated Voltage |

380V |

|||

Rated Power |

80KW |

120KW |

210KW |

250KW |

|

Vacuum |

Conventional Vacuum Pumps |

<5×10-2mbar |

|||

High Vacuum Pumps |

<5×10-5mbar |

||||

Leak Rate |

<5×10-3mbar·l/sec |

||||

Quenching Oil Tank |

Working Temperature |

60-130℃ |

|||

Oil Volume |

2000L |

4300L |

8000L |

12000L |

|

N2 Gas Cooling |

Pressure |

<2bar |

|||

Gross Charge Weight |

200KG |

600KG |

1000KG |

1500KG |

|