Overview

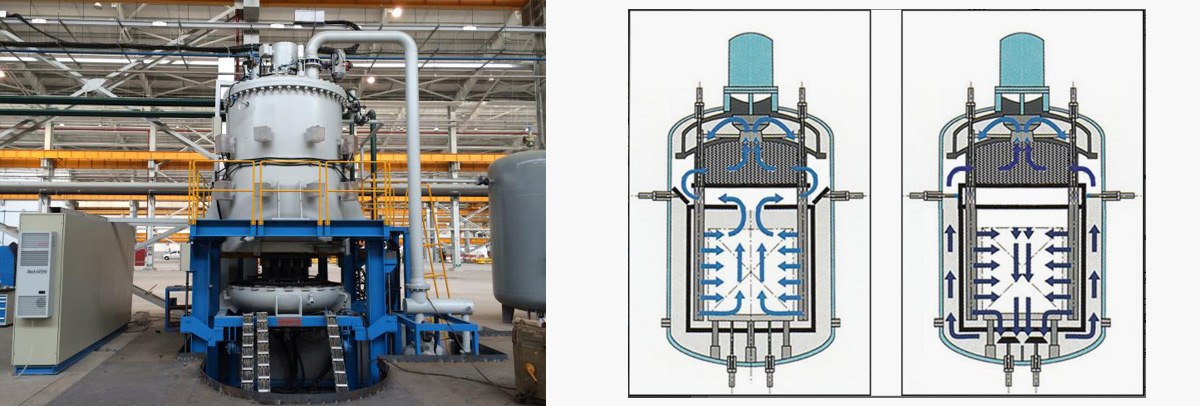

The vacuum heat treatment furnace, type VBNQ, is a resistance-heated furnace with a vertical, cylindrical hot zone and high pressure gas quenching.

Main Application

The furnace is used for hardening, tempering, annealing, sintering and brazing

◆Graphite Heating

Heater and insulation are made of graphite. The heating rods are installed in the thermal insulation.

◆Hot zone with Insulation

The insulation of the vertical cylindrical hot zone is made of hard felt graphite plates covered with graphite foil. The hard felt insulation, which is tight from all sides, reduces the thermal loss to a lower degree. The insulation material is extremely resistant and therefore wear and tear is relatively low.

◆Convective Heating

For better heat transfer to the material during heating convective heat transfer in the lower temperature range can be used. Therefore the furnace is flooded with inert gas (N2) after evacuation. The motor for the gas circulator is installed in the centre of the furnace bottom. The fan is made of fibre reinforced graphite (CFC)。 During convective operation an excellent temperature uniformity in the working space can be obtained with this system.

◆Heat Exchanger and Cooling Gas Circulation

The heat exchanger, consisting of ribbed tubes made from copper. Cooling water flows through the ribbed tubes. The selection of the material, geometrical shape and design of the ribbed tubes guarantee fine heat transfer possible, and therefore an efficient cooling of the circulated gas.

◆The cooling gas flows through a gas conduit from the hot zone to the gas cooler. Then it enters the hot zone from the nozzles fixed on graphite tubes which are displayed surround the hot zone. The out flow gas can be reversed up or down, and quenches the parts to be treated.

◆The gas flow during high pressure gas quenching has been optimized to obtain homogeneous and rapid quenching. Round gas spray flow and reverse gas outlet flow from bottom to top and top to bottom is possible.

◆The system is contolled by a state of the art Computer/PLC system. The user friendly software allows an easy operation. The software stores and protocolls all relevant process data for further use and trace abillity .

The rated temperature:1300 °C

Rated pressure of the quench gas:2/10 bar(abs)

The cooling gas:N2

Vacuum:<5×10-2mbar

Leak Rate:<5×10-3mbar ·l/sec

The furnace Can be customized according to customer's requirements.