Overview

Controlled atmosphere roller hearth furnace for salt-bath martensite & bainite is mainly used for bainite and martenite heat treatment of massive large-medium bearings ,such as metallurgy bearing, rolling mill bearing and railway bearing etc. Martensite quenching or bainite quenching of parts can be finished on the same production line. Before loading the parts, selecting martensite quenching process or bainite quenching process on the control system, then the process will be automatically executed according to selection.

Main Application

Salt-bath bainite austempering; Salt-bath martensite martempering.

◆Multi-purposes: The line can be used for various heat treatment, such as salt-bath bainite austempering, salt-bath martensite martempering, secondary quenching of carburized parts.

◆Fully sealed design: Fully sealed design of quenching tank and isothermal tank avoids environmental pollution caused by salt stream.

◆Non-oxidation: Controlled atmosphere of heating process and quenching transfer process allow treated parts to stay in the protective gas all the time, which ensures non-oxidation on the surface of parts.

◆Compact salt tank: Optimized design makes salt tank smaller and reduce the operation cost.

◆Stability: Using unique drive system, which is running stably in fused salt solution.

General Descriptions

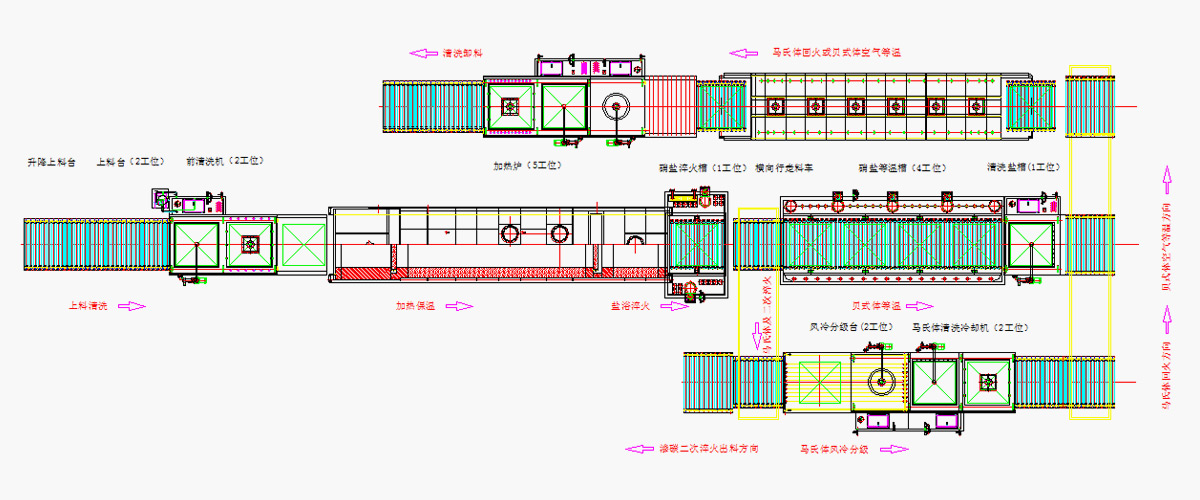

Controlled atmosphere roller hearth furnace for salt-bath martensite / bainite consists of roller hearth charging table, front cleaning machine, roller hearth heating furnace, salt-bath quenching tank, salt-bath isothermal tank, rear cleaning machine, double-deck air isothermal/tempering furnace, air cooling table and discharging table.

Working method

The bearing parts are placed on the loading table and automatically enter the roller bar heating furnace according to the cycle. After heating to the temperature (about 850°C) according to the process requirements, select nitrate martensitic stage quenching and tempering or bainite Austempering according to the process requirements: After the process is completed, clean, dry and unload the parts.

Item |

Description |

Productivity |

Dimension |

Though-put height |

Positions in heating furnace |

1 |

GRE 750/750/350-8 |

450kg/h |

750×750 |

350 |

8 |

2 |

GRE 1250/1250/350-6 |

800kg/h |

1200×1200 |

350 |

6 |

3 |

GRE 1500/1500/450-5 |

1000kg/h |

1500×1500 |

450 |

5 |